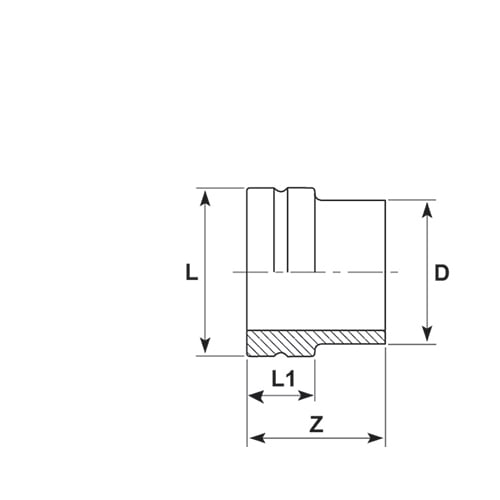

Shouldered Ends

Compression Camlock and Threaded Fittings

PE 100 shoulder ends give a new choice of connection and easy disconnection particularly to the mining industry. Not to be confused with roll groove, shouldered systems are normally utilised with steel pipe systems. Advanced Piping sees the need for flexibility, and noting the demand for two bolt clamps, we designed a weldable end to suit the Dixon, Minsup and Victaulic Clamps. Although HDPE shoulder ends won’t offer the pressure class of steel shouldered piping their excellent non-corrosive and abrasion resistance makes the combination of Poly Pipe with the two bolt steel clamps a perfect alternative for lower pressure dewatering and slurry applications. Advanced Piping shouldered ends also feature a double reinforced shoulder (second lump/ring) – this gives the pipe end additional hoop strength over single shouldered ends machined from a stub flange. Some contractors say that when they have a worn or scored end the second shoulder allows them to plane back to this, and keep using the pipe. This is easily done in a buttwelder by using the planer/facing tool. Available in stock SDR11 - Sizes 50mm to 450mm and SDR17, 90 to 450mm. We also machine special SDRs to order, as well as larger sizes in 500 and 630mm.

Compliance

Articles

Introducing Debottlenecking Video Series

Want to learn how to maximise efficiency in your next project? We’re excited to showcase the very first video of our Debottlenecking short video series. …

Barcode interpretation for Electrofusion Poly Welding

This morning, we received an urgent call from a customer out on site who wanted to double-check the weld time for a 63mm electrofusion socket. …

Beyond pipes – your mining questions answered

Mine projects are inherently unique, each presenting a set of challenges and specifications that require customised solutions. However, it’s often surprising how many of the …

Advanced Piping Systems’ precision HDPE spooling future-proofs iron ore mine

In 2022, Advanced Piping Systems supplied HDPE spooling and pipe to an A$100 million water management upgrade project at an iron ore mine in the …